Product overview

AUKEMA intelligent electric actuator, USES the international top design and manufacturing concept, noninvasive streamline structure, fully digital integrated chips, torque sensor detection technology, magnetoelectric encoder technology, English versions of the liquid crystal display, infrared remote control and wireless communications, bus communication network technology, etc., on the control better than imported brand optimization, closer to the automatic control requirements of the domestic market, is the electric power, petrochemical, environmental protection, smelting gold, the preferred brand for water treatment in areas such as valve control.

Functional features

Absolute magnetic encoder technology and power - off valve position display technology

AUKEMA series adopts the absolute value encoder with independent intellectual property rights, which can detect the number of turns up to 4000, the resolution of single turn is 4096 positions, and the absolute position travel detection with the total number of 24 bits. The unique design of low power battery power supply circuit, after the main power supply power, use battery power supply, continue to show the change of valve position. Absolute value encoder adopts magneto-electric technology, which has the characteristics of simple structure, stable performance, long service life, high precision and high resolution. The battery is only used to display the valve position after thousands of power consumption. Even if the battery is dead, absolute coding technology is adopted by thousands to continuously track the valve position change operated by hand wheel, which greatly improves the stability of the system.

Torque and force sensing technology

By adopting the advanced torque pressure sensing technology which is widely used in the world, AUKEMA electric actuator torque dynamic real-time high-precision detection is realized.Torque pressure sensing technology is tested and verified by industry practice.Precise, repeatable torque measurements can be obtained regardless of any change in frequency, voltage, and temperature.

Dual display LCD technology

The LCD screen adopts customized LCD, and adopts one-screen dual-display technology. The upper half of the screen adopts low-power segment type LCD display, which can display the valve position and alarm symbol in real time with thousands.The second half of the screen adopts graphics dot matrix liquid crystal display, which is used to display operation information and parameter setting.One-screen dual-display technology solves the problem of stability and reliability of two screens and improves the reliability and availability of the whole machine.

Bluetooth communication control and monitoring technology

Bluetooth communication remote control mode, to provide you with the convenience of computer and mobile phone remote control actuator, you can provide intelligent remote control software for local and remote analysis.

Double seal and non - invasive technology

IP68 protection grade, completely waterproof and dustproof."Double seal" ensures internal components are protected.Double protection of the knob is operated. Optional protective cover is added on the side of the knob panel, providing convenience for outdoor application of the protective knob.

All debugging and parameter setting can be completed without opening the cover of the box. Parameter setting and debugging can be done through magnetic control knob, infrared remote control or hand-held PDA.

Comprehensive protection and self-diagnosis function

A. Automatic phase sequence correction: automatically adjust the phase sequence to ensure that the three-phase motor always has the correct power phase sequence.To prevent valve damage caused by incorrect power connection.

B. Lack of phase protection: three-phase motor will overheat and burn out when running without phase.The controller monitors the three phases of the power supply.When - or multi-phase power supply is lost, if the motor is in motion, stop immediately;If the motor is static, it will be prevented from acting.At the same time, the power failure alarm will be displayed on the field LCD, and the remote indication information can be obtained from the configuration indicator contact.

C. Torque protection: the user can set different protection values of over-torque in on and off directions according to the field conditions (the range can be set as rated torque

When the actual torque borne by the electric actuator reaches or exceeds the set protection value, immediately stop the motor rotation and alarm.

D. Motor blocking protection: real-time monitoring of motor current can stop motor action in real time when motor blocking occurs.Protect motor and actuator.

E. Dead valve protection: when the actuator closes the limit and performs the valve opening action, it does not perform the torque protection function within a fixed period of time, and opens the valve in the stuck position with the maximum torque provided by the motor. If the valve cannot be opened after this period of time, the power supply to the motor will be cut off.

F. Motor overheating protection: if the coil is overheating, the two temperature regulators in the motor coil can directly detect the temperature of the motor coil.And disconnect the control circuit of the actuator.

G. Instantaneous reverse protection: when the actuator receives the instantaneous reverse command, the automatic delay circuit is used to prevent unnecessary wear of the valve stem and gear box caused by shock load.The circuit can also limit the surge current through a contactor.

H. automatic self-detection and diagnostic function (ASTD): at any time, once the actuator is connected to the power, it will automatically detect the operating circuit.To ensure correct operation.For thousands of rare device failures, it can be diagnosed and automatically displayed on the screen as an icon.At the same time, the electric operation of the valve actuator will be prohibited for easier field maintenance.

I. Data record protection: when the main power supply is off, the valve actuator stores various parameters in EEPROM, without loss for 20 years:

J. Anti-surge protection (lightning protection) : ac power anti-surge protection and signal anti-surge protection can be selected according to needs to achieve lightning protection of valve actuator.

K. Anti-condensation heating protection: the heating resistance can be opened or closed according to the temperature in the electrical cavity to achieve the anti-condensation heating protection of the valve actuator.

Local control

The AUKEMA actuator provides two non-invasive magnetic control knobs, one for the mode knob, with three positions: "in place", "remote" and "Stop"; The other is the operation button, which has two positions: "on" and "off". When the mode button is in place, turn the operation button to the "on" or "off" position controls the actuator action in the direction of "on" or "off". There are two ways of local control: "inching" and "holding".

The remote control

After the DCS or PLC is connected to the field actuator by hardwired cable, the actuator can be controlled by switch quantity (manual)/current flow (automatic).

Switch quantity control has three input terminals, namely valve opening, valve closing, stop/hold, optional inching and holding mode;In addition, the auxiliary switch quantity control is emergency protection (ESD), valve opening interlock and valve closing interlock.Remote input adopts photoelectric isolation and can resist 2.5kv surge.

Remote analog control adopts linear optocoupler isolation, and the valve can be positioned proportionally according to the input analog signal.

Remote analog valve position feedback, valve position can be fed back to DCS or PLC through 4-20ma signal;At the same time, remote analog torque feedback can be optionally provided.

ESD control

In an emergency, the ESD signal can override any field or remote signal (depending on parameter setting), enabling the actuator to enforce valve closing or valve opening. ESD operation can be selected as "valve closing", "valve opening" or "position preserving".

Interlock control

In applications where thousands of high requirements are required, the actuator can be configured to achieve conditional control.

In this mode, the operation depends on two independent signals.In the case of the valve closing command, the actuator closes the valve by providing a remote valve closing input signal and a valve closing interlock input signal.If only one signal is provided or one signal is lost, the actuator will hold or stop to prevent failure.For applications requiring ESD, dedicated ESD input can be used.This input has a high priority of thousands of local or remote control signals.Thus, any current or applied control signals are ignored when such signals are applied.

Diverse fieldbus connections

AUKEMA can be seamlessly connected to the fieldbus digital control system.Open fieldbus protocols, such as Profibus, Modbus,

Hart, FoundationFieldbus, and DeviceNet are all within AUKEMA's control.AUKEMA also first offers the ability to connect to industrial Ethernet, the industrial Ethernet based on the MODBUSTCP protocol, saving you PLC and directly connecting to SCADA systems.

By inserting the appropriate AUKEMA manufactured or supervised digital communication circuit board module into the actuator's electrical cavity - usually done at production time - it is easy and cost effective to operate. You can use the network test tool for the selected protocol for module testing and setup.

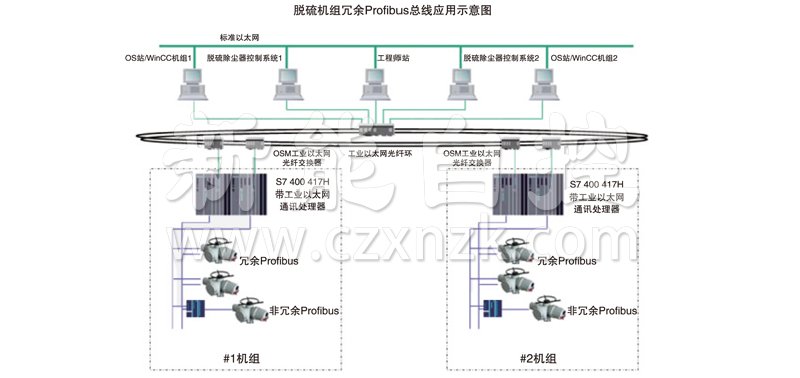

A) Profibus

In the field of industrial automation and control, Profibus is the most important network protocol for high-speed data communication in the world.

ProfibusDP interface: compatible with RS485ProfibusDPVO and V1, DPV2 bus protocol can be selected according to requirements;Optional single bus or double redundant bus;Fully accord with ec61158-3 standard;Support speed up to 1.5Mbit/s.

B) Modbus

Modbus is the most common serial communication protocol in automatic protocol application system.

AUKEMA's Modbus interface card allows the actuator to connect to the dual RS485 network.Thus using ModbusRTU protocol with PLC or DCS

Direct communication.The network can control and monitor the connected actuators.

Modbus interface: RS485 two-line RTU communication;International standards for open systems;Single and double redundant options;The built-in repeater module can be used under necessary application conditions.The maximum speed is 115KB.

It also provides the MODBUSTCP communication based on industrial Ethernet.It can be directly connected with SCADA system without PLC or controller connection, which can realize communication and control.

C) Hart

HART (Highway Addressable Remote Transducer), highway addressable remote sensor channels open communication protocols, is the United States

ROSEMOUNT introduced in 1985 a communication protocol between thousands of field smart meters and control room equipment.

Hart interface: accord with HART7.0 protocol standard. FSK frequency shift keying signals of Bell202 standard are supported, with carriers of 1200Hz and 2200Hz and communication rate of 1200b/S.

D) Foundation

Foundation Fieldbus is the most widely used process control system in petrochemical field. The main features in 1000 can be remotely deployed with DCS control system.

Foundation Fieldbus interface: supports direct connection to the standard FoundationH1 bus system; Fully accord with iec61158-2 standard; LinkMaster and LAS functions; Perfect HI field performance.

E) DeviceNet

DeviceNet is an open network standard, which is suitable for communication network using CAN bus in industrial environment.

DeviceNet interface: up to 63 devices per network;Four-wire cable (two for signals and two for thousands of power supplies);allow

Trunk and Drop lines;EDS electronic device description document.

Switching parameters

• working power supply:380VAC ±10% three-phase 50/60Hz 1%

220VAC ±10% single-phase 50/60Hz 1%

• switch input signal: 24VDC pulse or level signal, minimum duration of pulse signal 100ms;

• switch output signal: s1-s10;Relay output, contact rated capacity: 5a@250vac, 5a@30vdc;

• analog output: 4-20ma position signal;Load capacity up to 7500;Photoelectric isolation;Short circuit protection;Temperature effect of 0.1%/10K

•ambient temperature: -30℃~70℃ (specially customized -40℃~90℃);Humidity≦95%

• rated time: 10min,15min,30min

• insulation grade of motor: F

• working mode of motor: S2

• protection grade: IP67, IP68

• explosion-proof type: AK series explosion-proof grade ExdllBT4,ExdllCT4

•product conformity: GB/ t26155.2-2012 intelligent electric actuators for industrial process measurement and control systems - part 2: methods for performance evaluation

• product conformity: GB/ t28270-2012 intelligent valve electric device

Adjustable type technical parameters

•working power supply: three-phase: 380VAC ±10%, 50/60Hz ±1%; Single-phase: 220VAC+10%-15%, single-phase 50/60Hz ±1%

Special voltage: three-phase: 415V, 440V, 460V, 660V, 50/60hz

• analog input signal: 4-20ma;Photoelectric isolation, input impedance,2500

•analog output signal: 4-20ma position signal;Load capacity up to 7500;Photoelectric isolation;Short circuit protection;Temperature affects soil 0.1%/10K

• switch input: 24VDC pulse or level signal with a minimum duration of 100ms

•switch output: s1-s10;Relay output, contact rated capacity: 5a@250vac, 5a@30vdc

• ambient temperature: -30 7-70 (specially customized -40 7-90);Humidity; 95%

• adjustment times: up to 1200 times per hour

• insulation grade of motor: F

• motor operating system: S4

• basic errors :≦1%

• repeatability error of stroke control mechanism :≦1%

• dead zone: 0.1%-9.9% adjustable

• protection grade: IP67, IP68

• explosion-proof type: AK series explosion-proof grade ExdllBT4,ExdllCT4

•product conformity: GB/ t26155.2-2012 intelligent electric actuators for industrial process measurement and control systems - part 2: methods for performance evaluation

• product conformity: GB/ t28270-2012 intelligent valve electric device

• working mode of motor: S2

• protection grade: IP67, IP68

• explosion-proof type: AK series explosion-proof grade ExdllBT4,ExdllCT4

• product conformity: GB/ t26155.2-2012 intelligent electric actuators for industrial process measurement and control systems - part 2: methods for performance evaluation

• product conformity: GB/ t28270-2012 intelligent valve electric device

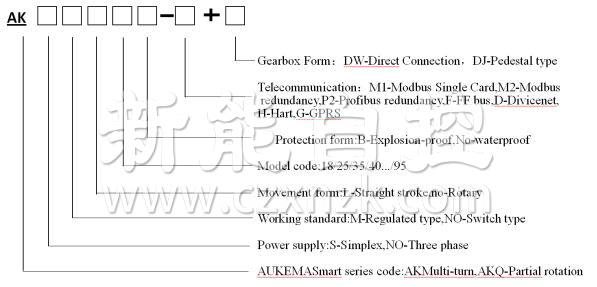

Description of product model compilation