Electric flange ball valve

Simple introduction

Q941F electric flange ball valve has the same 90-degree rotation lifting action, with circular through hole or channel passing through its axis. The ratio between the sphere and the channel opening should be like this, that is, when the ball rotates 90 degrees, the inlet and outlet should all present a sphere, thus cutting off the flow.

The operation of the electric flagged ball valves only need to rotate 90 degrees and small rotational torque can be closed tightly, full equality of the valve body cavity for medium resistance is very small, straight flow channel, usually do think most suitable direct ball valve open and close, but in recent years has been the development of ball valve designed to make it with throttling and control flow.The main characteristics of the ball valve is its compact structure, easy thousand operation and maintenance, suitable for thousand water, solvent, acid and natural gas, general working medium, but also suitable for thousand working conditions, such as oxygen, hydrogen peroxide, home and ethylene, etc.Ball valve body can be a whole, can also be combined.

Technical parameters

|

Optional functions of electric actuator |

switch type, integral type, adjusting type, intelligent type |

|

Optional models of electric actuator |

Q, DQ, QM, QC, AKQ series;Z series and AK seriesfor large caliber |

|

Voltage |

AC220V, AC110V, AC380V, DC12V, DC24V, DC110V |

|

Nominal diameter |

DN15mm~DN200mm |

|

Nominal pressure |

PN1.0MPa~PN2.5MPa |

|

Applicable temperature |

PTEE:-30~ +120℃ PPL:≦350℃ metal seal:≦450℃ |

|

Connection mode |

flange type |

|

Body material |

cast iron, cast steel, 304, 316, 316L |

|

Valve plate material |

304, 316, 316L |

|

Seat lining |

PTEE, PPL, metal seal |

|

Suitable medium |

water, petroleum, acid, viscous fluid, slurry medium, etc. |

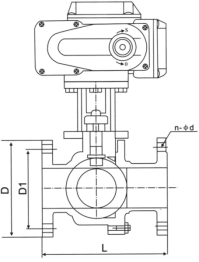

Structure diagram

Main dimension table

|

DN (mm) |

1.0MPa |

1.6MPa |

2.5MPa |

4.0MPa |

||||||||||||

|

L |

D |

D1 |

n-Φd |

L |

D |

D1 |

n-Φd |

L |

D |

D1 |

n-Φd |

L |

D |

D1 |

n-Φd |

|

|

15 |

130 |

95 |

65 |

4-Φ14 |

130 |

95 |

65 |

4-Φ14 |

130 |

95 |

65 |

4-Φ14 |

130 |

95 |

65 |

4-Φ14 |

|

20 |

140 |

105 |

75 |

4-Φ14 |

140 |

105 |

75 |

4-Φ14 |

140 |

105 |

75 |

4-Φ14 |

140 |

105 |

75 |

4-Φ14 |

|

25 |

150 |

115 |

85 |

4-Φ14 |

150 |

115 |

85 |

4-Φ14 |

150 |

115 |

85 |

4-Φ14 |

150 |

115 |

85 |

4-Φ14 |

|

32 |

165 |

135 |

100 |

4-Φ18 |

165 |

135 |

100 |

4-Φ18 |

165 |

135 |

100 |

4-Φ18 |

180 |

135 |

100 |

4-Φ18 |

|

40 |

180 |

145 |

110 |

4-Φ18 |

180 |

145 |

110 |

4-Φ18 |

180 |

145 |

110 |

4-Φ18 |

200 |

145 |

110 |

4-Φ18 |

|

50 |

200 |

160 |

125 |

4-Φ18 |

200 |

160 |

125 |

4-Φ18 |

200 |

160 |

125 |

4-Φ18 |

220 |

160 |

125 |

4-Φ18 |

|

65 |

220 |

180 |

145 |

4-Φ18 |

220 |

180 |

145 |

4-Φ18 |

220 |

180 |

145 |

8-Φ18 |

250 |

180 |

145 |

8-Φ18 |

|

80 |

250 |

195 |

160 |

4-Φ18 |

250 |

195 |

160 |

8-Φ18 |

250 |

195 |

160 |

8-Φ18 |

280 |

195 |

160 |

8-Φ18 |

|

100 |

280 |

215 |

180 |

8-Φ18 |

280 |

215 |

180 |

8-Φ18 |

280 |

230 |

190 |

8-Φ23 |

320 |

230 |

190 |

8-Φ23 |

|

125 |

320 |

245 |

210 |

8-Φ18 |

320 |

245 |

210 |

8-Φ18 |

320 |

270 |

220 |

8-Φ25 |

400 |

270 |

220 |

8-Φ25 |

|

150 |

360 |

280 |

240 |

8-Φ23 |

360 |

280 |

240 |

8-Φ23 |

360 |

300 |

250 |

8-Φ25 |

400 |

300 |

250 |

8-Φ25 |

|

200 |

400 |

335 |

295 |

8-Φ23 |

400 |

335 |

295 |

12-Φ23 |

400 |

360 |

310 |

12-Φ25 |

502 |

375 |

310 |

12-Φ30 |