Simple introduction

D641H pneumatic clamp hard seal butterfly valve adopts three partial hardness seal structure design, through strict calculation, "U" type sealing ring and butterfly plate almost frictionless, solve the traditional eccentric butterfly valve in the opening and closing 0 to 10 degrees instantaneous sealing surface are still thousands of sliding friction ills, realize the butterfly plate in open the instant sealing surface, the separation, close contact with the sealing effect and prolong the service life, sealed performance is the best.

The sealing surface of butterfly plate is made of butt-welding and drilling base hard alloy, and the sealing surface is resistant to wear. The large-sized butterfly plate is made of spinning frame mechanism, featuring high strength, large flow area and small flow resistance., "On and off" is accomplished by simply turning the stem 90°. Therefore hard seal butterfly valve is widely used in the medium temperature≤425℃metallurgical, electric power, petroleum, chemical industry, air, gas, combustible gas and water supply and drainage and other corrosive media pipeline, as the best device to regulate the flow and cut off the fluid. Products in line with national GB/ t13927-92 valve pressure test standards.

Technical parameters

|

Optional functions of electric actuator |

double acting, single acting |

|

Optional models of electric actuator |

AT series, AW series |

|

Voltage |

AC110V, AC220V, AC24V,DC24V |

|

Air source pressure |

2bar-8bar |

|

Nominal diameter |

DN50mm~DN1200mm |

|

Nominal pressure |

PN1.0MPa~PN2.5MPa |

|

Applicable temperature |

-30~ +425℃ |

|

Connection mode |

sandwich type |

|

Body material |

carbon steel, stainless steel |

|

Valve plate material |

carbon steel, stainless steel, alloy steel, etc. |

|

Seat lining |

hard alloy, carbon pigeon, silver alloy, graphite compound |

|

Suitable medium |

water liquid,steam, oil, weak corrosive medium, etc. |

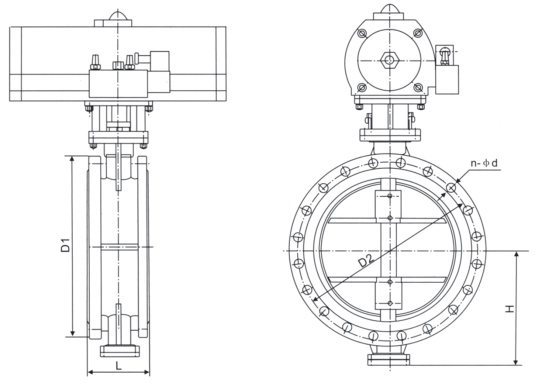

Structure diagram

Main dimension table

|

DN |

1.0 |

1.6 |

||||||||

|

(mm) |

L |

H |

D |

D1 |

n-Φd |

H |

L |

D |

D1 |

n-Φd |

|

50 |

43 |

85 |

125 |

100 |

4-Φ18 |

43 |

85 |

125 |

100 |

4-Φ18 |

|

65 |

46 |

95 |

145 |

120 |

4-Φ18 |

46 |

95 |

145 |

120 |

4-Φ18 |

|

80 |

49 |

110 |

160 |

135 |

4-Φ18 |

64 |

110 |

160 |

135 |

8-Φ18 |

|

100 |

56 |

122 |

180 |

155 |

8-Φ18 |

64 |

122 |

180 |

155 |

8-Φ18 |

|

125 |

64 |

138 |

210 |

185 |

8-Φ18 |

70 |

138 |

210 |

185 |

8-Φ18 |

|

150 |

70 |

158 |

240 |

210 |

8-Φ22 |

76 |

158 |

240 |

210 |

8-Φ22 |

|

200 |

71 |

188 |

295 |

265 |

8-Φ22 |

89 |

188 |

295 |

265 |

12-Φ22 |

|

250 |

76 |

224 |

350 |

320 |

12-Φ22 |

114 |

224 |

350 |

320 |

12-Φ26 |

|

300 |

83 |

254 |

400 |

368 |

12-Φ22 |

114 |

254 |

400 |

368 |

12-Φ26 |

|

350 |

92 |

288 |

460 |

428 |

16-Φ22 |

127 |

288 |

460 |

428 |

16-Φ26 |

|

400 |

102 |

320 |

515 |

482 |

16-Φ26 |

140 |

320 |

515 |

482 |

16-Φ30 |

|

450 |

114 |

350 |

565 |

532 |

20-Φ26 |

152 |

350 |

565 |

532 |

20-Φ30 |

|

500 |

127 |

388 |

620 |

585 |

20-Φ26 |

152 |

388 |

620 |

585 |

20-Φ33 |

|

600 |

154 |

440 |

725 |

685 |

20-Φ30 |

178 |

440 |

725 |

685 |

20-Φ36 |

|

700 |

165 |

488 |

840 |

800 |

24-Φ30 |

229 |

488 |

840 |

800 |

24-Φ30 |

|

800 |

190 |

572 |

950 |

905 |

24-Φ33 |

241 |

572 |

950 |

905 |

24-Φ39 |

|

900 |

203 |

628 |

1050 |

1005 |

28-Φ33 |

241 |

628 |

1050 |

1005 |

28-Φ39 |

|

1000 |

216 |

698 |

1160 |

1115 |

28-Φ36 |

300 |

698 |

1160 |

1115 |

28-Φ42 |

|

1200 |

254 |

810 |

1380 |

1325 |

32-Φ39 |

360 |

810 |

1380 |

1325 |

32-Φ48 |