Electric desulfurization on clip butterfly valve

Simple introduction

D971 XT electric desulfurization clamp butterfly valve is a product designed by our company according to the current domestic flue gas desulfurization system.In order to adapt to the corrosion of limestone slurry and stone paste slurry, the valve plate and stem are made of special corrosion resistant alloy, and the valve seat is made of high wear-resistant rubber, which is adapted to the erosion of the valve seat by a large number of suspended particles in the liquid.The products are designed according to user requirements, so it is targeted and high reliability.

Suitable medium for gypsum ash, sulfur dioxide, limestone paste slurry, process water and other corrosive media.

Technical parameters

|

Optional functions of electric actuator |

switch type, integral type, adjusting type, intelligent type |

|

Optional models of electric actuator |

Q, DQ, QM, QC, AKQ series;Z series and AK seriesfor large caliber |

|

Voltage |

AC220V, AC110V, AC380V, DC12V, DC24V, DC110V |

|

Nominal diameter |

DN25mm~DN1400mm |

|

Nominal pressure |

PN1.0MPa~PN1.6MPa |

|

Applicable temperature |

EPDM:-30~+100℃ PTEE:-30~+120℃ |

|

Connection mode |

sandwich type, U type |

|

Body material |

spheroidal ink, carbon steel, stainless steel |

|

Valve plate material |

2507, 1.4529 |

|

Seat lining |

NBR,EPDM,PTFE |

|

Suitable medium |

gypsum ash, sulfur dioxide, limestone paste, process water, etc. |

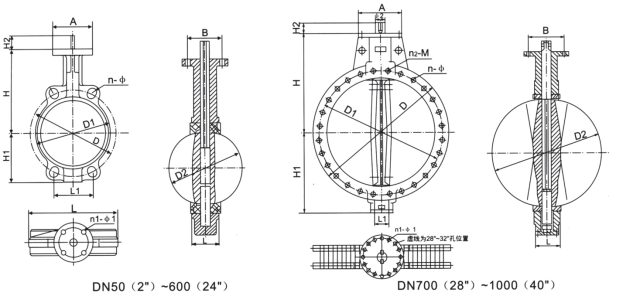

Structure diagram

Main dimension table

|

DN |

H |

H1 |

H2 |

L |

L1 |

D |

D1 |

D2 |

n-Φ |

n1-Φ1 |

A |

B |

circular |

square |

flat |

n2-M |

|

|

mm |

inch |

Φ2 |

Φ2 |

Φ2 |

|||||||||||||

|

50 |

2" |

146 |

68 |

32 |

42 |

84.84 |

120 |

118 |

52.9 |

4-Φ23 |

4-Φ6.7 |

90 |

70 |

12.6 |

9X9 |

10 |

- |

|

65 |

2.5" |

152 |

75 |

32 |

44.7 |

96.2 |

136.2 |

137 |

64.5 |

4-Φ26.5 |

4-Φ6.7 |

90 |

70 |

12.6 |

9X9 |

10 |

- |

|

80 |

3" |

163 |

93 |

32 |

45.2 |

61.23 |

160 |

143 |

78.8 |

8-Φ18 |

4-Φ6.7 |

90 |

70 |

12.6 |

9X9 |

10 |

- |

|

100 |

4" |

173 |

104 |

32 |

52.1 |

70.80 |

185 |

156 |

104 |

4-Φ24.5 |

4-Φ10.3 |

90 |

70 |

15.77 |

11X11 |

12 |

- |

|

125 |

5" |

194 |

118 |

32 |

54.4 |

82.28 |

215 |

190 |

123.3 |

4-Φ23 |

4-Φ10.3 |

90 |

70 |

18.92 |

14X14 |

14 |

- |

|

150 |

6" |

206 |

133 |

32 |

55.8 |

91.08 |

238 |

212 |

155.6 |

4-Φ25 |

4-Φ10.3 |

90 |

70 |

18.92 |

14X14 |

14 |

- |

|

200 |

8" |

234 |

165 |

45 |

60.6 |

112.89 |

295 |

268 |

202.5 |

4-Φ25 |

4-Φ14.3 |

125 |

102 |

22.1 |

17X17 |

17 |

- |

|

76.35 |

4-Φ23 |

||||||||||||||||

|

250 |

10" |

271 |

197 |

45 |

65.6 |

92.40 |

357 |

325 |

250.5 |

4-Φ29 |

4-Φ14.3 |

125 |

102 |

28.45 |

22X22 |

22 |

- |

|

300 |

12" |

309 |

224 |

45 |

76.9 |

105.34 |

407 |

403 |

301.6 |

4-Φ29 |

4-Φ14.3 |

125 |

102 |

31.6 |

22X22 |

24 |

- |

|

250 |

14" |

368 |

267 |

45 |

76.5 |

91.11 |

467 |

436 |

333.3 |

4-Φ30 |

4-Φ14.3 |

125 |

102 |

31.6 |

22X22 |

24 |

- |

|

400 |

16" |

400 |

309 |

51.2 |

86.5 |

100.47 |

515 |

488 |

389.6 |

4-Φ26 |

4-Φ20.6 |

175 |

140 |

33.15 |

- |

- |

- |

|

72 |

102.42 |

525 |

4-Φ30 |

||||||||||||||

|

450 |

18" |

422 |

328 |

51.2 |

105.6 |

88.39 |

565 |

539 |

440.51 |

4-Φ26 |

4-Φ20.6 |

175 |

140 |

38 |

- |

- |

- |

|

72 |

91.51 |

585 |

4-Φ30 |

||||||||||||||

|

500 |

20" |

480 |

361 |

64.2 |

131.8 |

96.99 |

620 |

593 |

491.6 |

4-Φ26 |

4-Φ20.6 |

175 |

140 |

41.15 |

- |

- |

- |

|

82 |

101.68 |

650 |

4-Φ33 |

||||||||||||||

|

600 |

24" |

562 |

459 |

70.2 |

152 |

113.42 |

725 |

816 |

592.5 |

20-Φ30 |

4-Φ22.2 |

210 |

165 |

50.65 |

- |

- |

- |

|

82 |

120.46 |

770 |

20-Φ36 |

||||||||||||||

|

700 |

28" |

624 |

420 |

66 |

163 |

109.65 |

840 |

895 |

695 |

24-Φ30 |

8-Φ18 |

300 |

254 |

63.35 |

- |

- |

4-M33 |

|

82 |

20-Φ36 |

||||||||||||||||

|

800 |

32" |

672 |

591 |

66 |

188 |

124 |

950 |

1015 |

764.7 |

24-Φ33 |

8-Φ18 |

300 |

254 |

63.35 |

- |

- |

- |

|

82 |

24-Φ39 |

||||||||||||||||

|

900 |

36" |

720 |

656 |

118 |

203 |

117.57 |

1050 |

1115 |

864.7 |

24-Φ33 |

8-Φ18 |

300 |

254 |

75 |

- |

- |

4-M30 |

|

1000 |

40" |

800 |

721 |

142 |

216 |

129.89 |

1160 |

1230 |

965 |

24-Φ36 |

8-Φ18 |

300 |

254 |

85 |

- |

- |

4-M33 |