Electric ventilation butterfly valve

Simple introduction

D941W electric ventilation butterfly valve is suitable for cutting off the ventilation of thousands of pairs. The connection between the valve and the actuator is in the form of branch connection. The electric actuator does not need to be equipped with servo amplifier.

The ventilation butterfly valve USES the mid-line butterfly plate and the short structure copper plate welding new structure form design manufacture, USES the high quality wear-resisting material to weld, the structure is compact, the weight is light, easily installs, the flow resistance is small, the circulation flux is big, avoids the high temperature expansion influence, the operation is light. No connecting rod, bolt, reliable work, long service life, especially suitable for low-pressure difference, large diameter, large flow occasions, it is used with various actuator combination, combination into different performance of the valve, can be multi-station installation, not affected by the flow direction of medium. Ventilation butterfly valve is an unsealed butterfly valve, widely applicable to thousands of ventilation dust removal system, dust containing gas, gas pipeline, ventilation purification device, flue gas pipeline, medium temperature≤300℃nominal pressure is -0.1mpa on the pipeline, used to connect, open and close or adjust the medium quality.

Technical parameters

|

Optional functions of electric actuator |

switch type, integral type, adjusting type, intelligent type |

|

Optional models of electric actuator |

Q, DQ, QM, QC, AKQ series;Z series and AK seriesfor large caliber |

|

Voltage |

AC220V, AC110V, AC380V, DC12V, DC24V, DC110V |

|

Nominal diameter |

DN50mm~DN1200mm |

|

Nominal pressure |

PN1.0MPa~PN2.5MPa |

|

Applicable temperature |

-30~+425℃ |

|

Connection mode |

sandwich type |

|

Body material |

carbon steel, stainless steel |

|

Valve plate material |

carbon steel, stainless steel, alloy steel, etc. |

|

Seat lining |

hard alloy, carbon pigeon, silver alloy, graphite compound,tetrafluoro |

|

Suitable medium |

liquid water, steam, oil, weak corrosive medium, etc. |

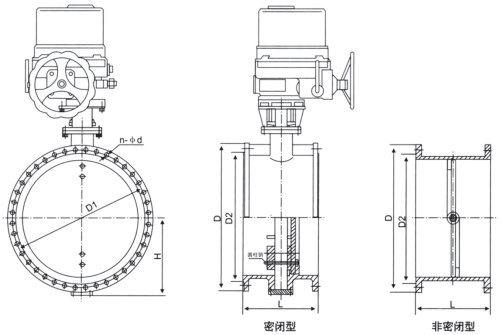

Structure diagram

Main dimension table

|

DN |

L |

H |

0.05-0.1 MPa |

0.25MPa |

0.6MPa |

|||||||||

|

(mm) |

D |

D1 |

D2 |

n-Φd |

D |

D1 |

D2 |

n-Φd |

D |

D1 |

D2 |

n-Φd |

||

|

50 |

108 |

70 |

140 |

110 |

88 |

4-Φ14 |

140 |

110 |

88 |

4-Φ14 |

140 |

110 |

88 |

4-Φ14 |

|

65 |

112 |

80 |

160 |

130 |

108 |

4-Φ14 |

160 |

130 |

108 |

4-Φ14 |

160 |

130 |

108 |

4-Φ14 |

|

80 |

114 |

95 |

190 |

150 |

124 |

4-Φ18 |

190 |

150 |

124 |

4-Φ18 |

190 |

150 |

124 |

4-Φ19 |

|

100 |

127 |

105 |

210 |

190 |

144 |

4-Φ18 |

210 |

190 |

144 |

4-Φ18 |

210 |

190 |

144 |

4-Φ19 |

|

125 |

140 |

120 |

240 |

200 |

174 |

8-Φ18 |

240 |

200 |

174 |

8-Φ18 |

240 |

200 |

174 |

8-Φ19 |

|

150 |

140 |

132 |

265 |

225 |

199 |

8-Φ18 |

265 |

225 |

199 |

8-Φ18 |

265 |

225 |

199 |

8-Φ19 |

|

200 |

152 |

160 |

320 |

280 |

254 |

8-Φ18 |

320 |

280 |

254 |

8-Φ18 |

320 |

280 |

254 |

8-Φ19 |

|

250 |

165 |

187 |

375 |

335 |

309 |

12-Φ18 |

375 |

335 |

309 |

12-Φ18 |

375 |

335 |

309 |

12-Φ19 |

|

300 |

180 |

220 |

440 |

395 |

363 |

12-Φ22 |

440 |

395 |

363 |

12-Φ22 |

440 |

395 |

363 |

12-Φ23 |

|

350 |

180 |

245 |

490 |

445 |

413 |

12-Φ22 |

490 |

445 |

413 |

12-Φ22 |

490 |

445 |

413 |

12-Φ23 |

|

400 |

200 |

270 |

540 |

495 |

463 |

16-Φ22 |

540 |

495 |

463 |

16-Φ22 |

540 |

495 |

463 |

16-Φ23 |

|

450 |

200 |

297 |

595 |

550 |

518 |

16-Φ22 |

595 |

550 |

518 |

16-Φ22 |

595 |

550 |

518 |

16-Φ23 |

|

500 |

220 |

322 |

645 |

600 |

568 |

20-Φ22 |

645 |

600 |

568 |

20-Φ22 |

645 |

600 |

568 |

20-Φ23 |

|

600 |

220 |

377 |

755 |

705 |

667 |

20-Φ26 |

755 |

705 |

667 |

20-Φ26 |

755 |

705 |

667 |

20-Φ26 |

|

700 |

240 |

430 |

860 |

810 |

772 |

24-Φ26 |

860 |

810 |

772 |

24-Φ26 |

860 |

810 |

772 |

24-Φ26 |

|

800 |

240 |

487 |

975 |

920 |

878 |

24-Φ30 |

975 |

920 |

878 |

24-Φ30 |

975 |

920 |

878 |

24-Φ31 |

|

900 |

260 |

537 |

1075 |

1020 |

978 |

24-Φ30 |

1075 |

1020 |

978 |

24-Φ30 |

1075 |

1020 |

978 |

24-Φ31 |

|

1000 |

260 |

587 |

1175 |

1120 |

1078 |

28-Φ30 |

1175 |

1120 |

1078 |

28-Φ30 |

1175 |

1120 |

1078 |

28-Φ31 |

|

1200 |

280 |

702 |

1375 |

1320 |

1280 |

32-Φ30 |

1375 |

1320 |

1280 |

32-Φ30 |

1405 |

1340 |

1295 |

32-Φ34 |

|

1400 |

300 |

782 |

1575 |

1520 |

1480 |

36-Φ30 |

1575 |

1520 |

1480 |

36-Φ30 |

1630 |

1560 |

1510 |

36-Φ37 |

|

1600 |

320 |

895 |

1790 |

1730 |

1690 |

40-Φ30 |

1790 |

1730 |

1690 |

40-Φ30 |

1830 |

1760 |

1710 |

40-Φ37 |

|

1800 |

340 |

995 |

1990 |

1930 |

1890 |

44-Φ30 |

1990 |

1930 |

1890 |

44-Φ30 |

2045 |

1970 |

1918 |

44-Φ40 |

|

2000 |

360 |

1095 |

2190 |

2130 |

2090 |

48-Φ30 |

2190 |

2130 |

2090 |

48-Φ30 |

2265 |

2180 |

2125 |

48-Φ43 |

|

2200 |

380 |

1200 |

2405 |

2340 |

2295 |

52-Φ33 |

2405 |

2340 |

2295 |

52-Φ33 |

2475 |

2390 |

2335 |

52-Φ43 |

|

2400 |

400 |

1310 |

2605 |

2540 |

2495 |

56-Φ33 |

2605 |

2540 |

2495 |

56-Φ33 |

2685 |

2600 |

2545 |

56-Φ43 |

|

2600 |

420 |

1420 |

2805 |

2740 |

2695 |

60-Φ33 |

2805 |

2740 |

2695 |

60-Φ33 |

2905 |

2810 |

2750 |

60-Φ49 |

|

2800 |

440 |

1530 |

3030 |

2960 |

2910 |

64-Φ36 |

3030 |

2960 |

2910 |

64-Φ36 |

3115 |

3020 |

2960 |

64-Φ49 |

|

3000 |

460 |

1640 |

3230 |

3160 |

3110 |

68-Φ36 |

3230 |

3160 |

3110 |

68-Φ36 |

3315 |

3220 |

3160 |

68-Φ49 |

|

3200 |

480 |

1760 |

3430 |

3360 |

3310 |

72-Φ36 |

3430 |

3360 |

3310 |

72-Φ36 |

3525 |

3430 |

3360 |

72-Φ49 |

|

3400 |

500 |

1870 |

3630 |

3560 |

3510 |

76-Φ36 |

3630 |

3560 |

3510 |

76-Φ36 |

3735 |

3640 |

3560 |

76-Φ49 |

|

3600 |

520 |

1980 |

3840 |

3770 |

3720 |

80-Φ36 |

3840 |

3770 |

3720 |

80-Φ36 |

3970 |

3860 |

3720 |

80-Φ56 |

|

3800 |

540 |

2120 |

4045 |

3970 |

3920 |

80-Φ39 |

4045 |

3970 |

3920 |

80-Φ39 |

4180 |

4070 |

3970 |

80-Φ62 |

|

4000 |

560 |

2230 |

4245 |

4170 |

4120 |

84-Φ39 |

4245 |

4170 |

4120 |

84-Φ39 |

4380 |

4270 |

4170 |

84-Φ62 |